Tin Plating Features

.png)

.png)

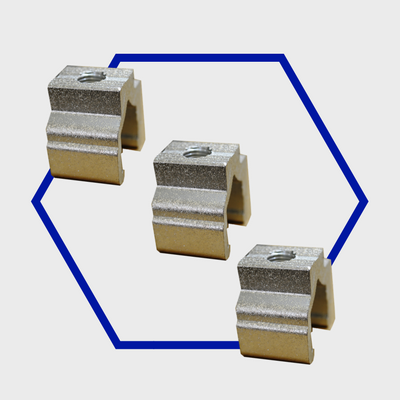

Tin plating is a very popular choice for a variety of industries. The two key factors in this are its cost effectiveness and corrosion resistance properties.

FDA approval

It might come as a surprise that tin cans are not actually made of tin! These cans are actually manufactured from sheet steel that is then coated with a thin layer of tin. Its wide use in the food industry means of course that Tin Plating is FDA approved.

Shielding

Tin is also popular with electrical manufacturers as a way of inhibiting oxidation. Both silver and copper have a natural tendency to oxidise and erode in exposed environments. A thin layer of tin can inhibit oxidation and will extend the life expectancy of components. Tin is none-magnetic, meaning it wouldn’t interfere in the use of RF components, and has a good level of electrical conductivity too making it useful for a variety of electrical components.

Resistance

Tin plating provides components with a good level of wear resistance, and is not sensitive to stain through finger touch. It also provides a high level of corrosion resistance, and in particular is very chemically resistant. This affords tin plated steel components with a very good level of protection for the price point.

What Silchrome Offer

Silchrome Plating offer both Dull and Bright Acid Tin Plating. We can meet a number of specifications including: ASTM B545, MIL-T-10757, BS1872, Def Stan 03-08. All of our plating takes place in our headquarters in Leeds, West Yorkshire.